Right, this here #39 dado plane then. I decided I'd sharpen up the blade and spur cutters and see how it went, rather than leap into correcting stuff that might not even need it. The iron looked pretty rough but polished up very quickly. This is a Bad Thing - suggesting, as it does, that the blade has all the edge-holding ability of a processed cheese slice. Oh well.

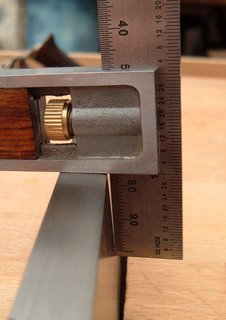

The nickers? Well judge for yourself if I was justified in having some doubts about them. At least, being soft as butter, it was easy to turn the bevel into something approaching an edge.

The bevel end is the one on the left in both pics - possibly not immediately obvious in the side-on shot...

The blade bed is a fetching shade of blue - all over. D'oh.

I looked at it, shuddered, and stopped looking. To be fair the bottom few millimeters

is milled (and then painted) but only the extreme forward point of the blade is supported on it.

The rest is suspended in mid air. If this thing works it's going to be a miracle...

On the other hand, the blade width was spot on and I was able to set it just right between the two spur cutters without the fiddling I'd feared.

But hey, miracles do happen sometimes, so I took it for a spin. I can see exactly what

Blood & Gore means about them being uncomfortable for the front hand. I managed in the end by bridging over the obstacles on the toe in a sort of pinching holding.

Okay for a short test run, but not great for any quantity of use. On the other hand there aren't many scruples floating about when it comes to tapping a 20 quid plane made the day before yesterday, so something might be done about it.

So after all that, so many "oo, you don't want that feature on your plane, missus" boxes ticked, how did it perform actually doing the job for which it was intended? Dammit, the blasted thing worked a treat!

Yeah, okay, so I had to concentrate on holding it plumb 'cos the sole wasn't, and it just about managed two 1/4" deep housings before the iron needed sharpening again, but really, it was pretty damn good.

I might take the trouble to square up the sole a little better, just to let me be lazy when it comes to using it, and something about the front grip would be nice - but on the whole it ain't broke so I don't see myself fixing it.

Unless I get really bored one rainy day...

I believe hiatus projectus has struck again; an inability to immediately go onto the next project having completed the previous one. You'd think I'd be starting the next one before finishing the last by now, wouldn't you? But no, dumbo here falls into the same bout of Woodworker's Block every time. And to be fair I had to devote myself whole-heartedly to The Chair at the end, to get it done in time. Even then is was a "damn close run thing". So stopping off to plane up that chestnut, f'rinstance, just wasn't on the cards. 'Specially when you're using the planer thicknesser as a worktop at the time. Ha hum.

I believe hiatus projectus has struck again; an inability to immediately go onto the next project having completed the previous one. You'd think I'd be starting the next one before finishing the last by now, wouldn't you? But no, dumbo here falls into the same bout of Woodworker's Block every time. And to be fair I had to devote myself whole-heartedly to The Chair at the end, to get it done in time. Even then is was a "damn close run thing". So stopping off to plane up that chestnut, f'rinstance, just wasn't on the cards. 'Specially when you're using the planer thicknesser as a worktop at the time. Ha hum.

I haven't been away that long in years; not sure what I'll do with myself parted from my keyboard that long. Might have to prevail upon my bro to let me borrow his. Too bad he hasn't got a workshop as well, but with luck I'll be able to take in some local sites of woodworking interest to keep the withdrawal symptoms at bay. And I know someone'll ask in the comments - it's the Kent/Sussex border. Not far from Timberline, purveyor of exotic timbers, funnily enough. Hmm, plane totes, chisel handles, plot, plot..

I haven't been away that long in years; not sure what I'll do with myself parted from my keyboard that long. Might have to prevail upon my bro to let me borrow his. Too bad he hasn't got a workshop as well, but with luck I'll be able to take in some local sites of woodworking interest to keep the withdrawal symptoms at bay. And I know someone'll ask in the comments - it's the Kent/Sussex border. Not far from Timberline, purveyor of exotic timbers, funnily enough. Hmm, plane totes, chisel handles, plot, plot..

So I'm sitting here going "ouch" and thanking my lucky stars that I've never learnt to type beyond three fingers - none of which are the effected digit. (Or should that be affected? I always get those wrong)

So I'm sitting here going "ouch" and thanking my lucky stars that I've never learnt to type beyond three fingers - none of which are the effected digit. (Or should that be affected? I always get those wrong)

I haven't cleaned the saws yet (yes, Mike, that's the Disston I didn't want to bore you with) but the little craftsman-made calipers I've only just cleaned up from last month. Very cute. I'll tell you about the panel saw some other time maybe. It's only a modern one, but the etch is clear and at the price...

I haven't cleaned the saws yet (yes, Mike, that's the Disston I didn't want to bore you with) but the little craftsman-made calipers I've only just cleaned up from last month. Very cute. I'll tell you about the panel saw some other time maybe. It's only a modern one, but the etch is clear and at the price... I do seem to be rather awash with 3/8" chisels at the moment though. It's a hard life.

I do seem to be rather awash with 3/8" chisels at the moment though. It's a hard life.

On the other hand, the blade width was spot on and I was able to set it just right between the two spur cutters without the fiddling I'd feared.

On the other hand, the blade width was spot on and I was able to set it just right between the two spur cutters without the fiddling I'd feared.

I might take the trouble to square up the sole a little better, just to let me be lazy when it comes to using it, and something about the front grip would be nice - but on the whole it ain't broke so I don't see myself fixing it.

I might take the trouble to square up the sole a little better, just to let me be lazy when it comes to using it, and something about the front grip would be nice - but on the whole it ain't broke so I don't see myself fixing it.

Oh well, it's a known fact that combination planes are the one area of collecting I'll readily admit to, so I shouldn't be surprised I suppose...

Oh well, it's a known fact that combination planes are the one area of collecting I'll readily admit to, so I shouldn't be surprised I suppose...