Ah, Monday mornings; don'tcha just love 'em? Anyway, I hope I haven't over-sold this one...

Courtesy of the National Archives in Kew (reference ADM 106/241) via the generosity of Nicholas Blake, this is - well it's all explained in the letter really. It's the agreement on what and how many extra tools were to be issued for the benefit of the shipwrights' and caulkers' apprentices. I've done my best to transcribe it from the pics of the original accurately, but there may be a few slip-ups. First, the letter. And yes, it really does appear to say "conformably" and you thought management speak was a recent phenomenon...

Admiralty Office 1st December 1812

Gentlemen

Whereas by your letter of the 28th ultimo you have returned to us the abstract which we had transmitted to you containing our decision as to the number of tools to be allowed for the use of the additional numbers of boys prepared to be instructed on board His Majesty's Ships in the Shipwrights and Caulkers trades; and conformably to our directions you have sent us an account of the value of the said tools we do hereby desire and direct you to cause the additional tools specified in the enclosed Account to be allowed to the different Rates of His Majesty's Ships for the additional Boys proposed to be instructed in the Shipwrights and Caulkers trades. We further signify that the Carpenters of His Majesty's Ships are to be charged with the said tools, as with other stores and their expenditure is to be most carefully regulated observing that they are not to be made use of for any other purposes than those for which they are intended, we are,

Your affectionate friends

H Yorke

H Dundas

J Osborn

I do love the last bit; yes, we're letting you have these things, but we're watching you... "Affectionate friends" is a bit of a surprise though. Anyway, the enclosed account as mentioned is as follows. The numbers afterwards are the allotted quantity for certain ships based on their rates. Thus the first and second rates (the largest) are first, then third & fourth, fifth & sixth rates and finally "small vessels". So Axe 6.4.1.1 is 6 for the 1st & 2nd rates, 4 for the 3rd & 4th, and one each for the 5th, 6th and unrated vessels. "[?"] means I've made a best guess on the word based on shape and deduction but don't take it as gospel. Full descriptions are given for each tool simply because the blog can't cope with the formatting needed to present it as written.

Deptford Yard

25th Nov 1812

An account showing the usual[?] quantities of tools to be furnished for the use of the Boys who are prepared to be instructed on board H.M. Ships in the Shipwrights and Caulkers Trades.

Shipwrights Tools

Axes 6.4.1.1

Adzes, common 6.4.2.1

Adzes, compass 2.2.1.1

Saws, hand 6.4.2.1

Saws, compass 4.3.2.1

Mauls, pin [?] 4.3.2.1

Mauls, double headed 2.2.1.0

Hammers, claw 8.6.3.1

Hammers, sheathing 2.2.1.1

Hammers, clench 4.3.1.1

Chizles of 2 inches 4.3.2.1

Chizles of 1 1/2 inches 4.3.2.1

Chizles of 1 inch 4.3.2.1

Chizles of 3/4 inch 4.3.2.1

Chizles, Mortice 5/8 inch 1.1.1.1

Chizles, Mortice 1/2 inch 1.1.0.0

Chizles, Mortice 3/8 inch 1.1.1.1

Chizles, Mortice 1/4 inch 1.1.1.0

Gouges 2 1/2 inches 2.2.1.1

Gouges 2 inches 2.2.1.1

Gouges 1 1/2 inches 2.2.1.0

Gouges 1 inch 2.2.1.1

Slices 4 inches 2.2.1.1

Augers 1 1/2 inches 1.1.1.1

Augers 1 3/8 inches 1.1.1.0

Augers 1 1/4 inches 1.1.1.0

Augers 1 1/8 inches 1.1.1.1

Augers 1 inch 1.1.0.0

Augers 7/8 inch 1.1.1 .1

Augers 3/4 inch 1.1.0.0

Augers 5/8 inch 1.1.1.1

Gimblets 1/2 inch 2.2.1.1

Gimblets 3/8 inch 2.2.1.1

Gimblets small sorts 2.2.1.1

Planes, Jack 4.3.2.1

Planes, Smoothing 4.3.2.1

Drawing Knives 2.2.2.1

Rules 8.6.2.1

Squares, Iron 2.2.1.1

Lines [?] 4.3.2.1

Compasses 4.3.2.1

Stones, Turkey 2.2.1.1

Stones, Rag [?] 4.3.2.1

Spoke Shaves 2.2.1.1

Saw Set 2.2.1.1

Punches, nail 2.2.1.1

Punches, Socket for Boat [hook?] 2.2.1.1

Punches, brad 1.1.1.1

Mallets 4.4.2.1

Chest for Tools 1.1.1.1

Caulkers Tools

Mallets 4.3.2.1

Iron caulkings 4.3.2.1

Long 3.2.1.1

Spike 4.3.2.1

Meaking 4.3.2.1

Treenail 4.2.2.1

Sharp 4.3.2.1

Horsing 4.3.2.1

Reaming 4.3.2.1

Ladles 2.2.2.1

Beetles 2.2.2.1

Reaming [?] Hooks 4.3.2.1

I feel a distinct likelihood of finding myself taking Christopher Gabriel and the Tool Trade in 18th Century London off the shelf now. There's a comprehensive inventory taken in 1800 with values - reckon they wouldn't have changed that much and it might be interesting to see how much all that would have cost. But no, I won't be blogging that - this is bloomin' hard work!

Monday, October 30, 2006

Sunday, October 29, 2006

Blog Written in a Country Churchyard

With the clocks going back, Winter is truly upon us and all is woe and misery until the Spring. So naturally nature has gone "ya boo, that's what you think" and it's a beautiful sunny day. Putting aside the habit of a lifetime, I decided to go for a walk - just a couple of miles up to the local church and back, but that's more than enough for yours truly. Anyway, it dawned on me I've blogged the delights of views up country while on my travels but not the local scenery, so I donned my long coat, slipped my camera in my pocket, seized up a walking stick (obligatory wooden content) and set off. Must have looked a little incongruous with the iPod on too, but never mind...

I'll spare you the muddy lane, deep in leaf mould at the sides i.e. where you have to retreat whenever a car comes along. There was considerable evidence that squirrels had this way been - hazelnut and acorn husks everywhere. Gave a few brambles a thwack in the hopes of making the way a little easier for the next traveller, but they're tough old things and really needed a sword stick not a walking stick to make much impression. "Going" is much the worst, 'cos most of it's uphill, so I was much relieved to reach my goal and get a fine eyeballfull up the valley to Penryn and beyond to the blue ridge foothills of the china clay waste up by St Austell. These days the china clay folks get enviromental awards for flattening off the waste piles and making them green to "blend in" with the surrounding countryside (which they don't). But not that long ago they used to be left white and looked like snow-capped mountains, which was much more fun IMO. Heigh ho.

The church itself has an extremely picturesque pathway from the road, down paste high stone walls liberally coated with moss, ferns and worts of some sort, and an exceedlingly solid granite coffin rest and benches at the bottom. Of course that was for the benefit of the poor fellows who used to have to carry the coffin all the way, the church being well outside any of the villages it serves. No-one wants huffing and puffing pallbearers in church. I figured they wouldn't want a huffing and puffing me in the churchyard either, so I took advantage for a while too. That stone chills you to the bone though, so I soon moved on.

The world being as it is isolated country churches are kept locked, so I couldn't go in and look for decorative woodwork, but no matter 'cos there's a wonderful piece of carving in a granite doorframe. The green and orange that looks so extrordinary is actually moulds and lichen I believe - that doorway's in a particularly damp, North-facing spot.

Granite's the building material of choice for the whole church and most of the gravestones, as you might expect given that we're plumb in the middle of a load of granite quarries. Luckily that means the churchyard is spared weeping angels and other difficult-to-carve monuments, but soild oblongs and sturdy crosses abound. Having said which, this slate example caught my eye. Never come across a monumental mason putting a maker's mark on a headstone before. Mind you, Mr Vincent did a lovely job, so why not?

By this time I'd circled round to the other side of the church and was thinking of heading back. But I'd yet to get a halfway decent shot of the church itself. Tsk. Then I looked up from all the Kessels and Dunstans and Spargos and saw I had an Artistic Photo Opportunity. So, embracing the lens flare, I went for the silhouette and took a technically atrocious pic of a typical Cornish church.

I'll spare you the muddy lane, deep in leaf mould at the sides i.e. where you have to retreat whenever a car comes along. There was considerable evidence that squirrels had this way been - hazelnut and acorn husks everywhere. Gave a few brambles a thwack in the hopes of making the way a little easier for the next traveller, but they're tough old things and really needed a sword stick not a walking stick to make much impression. "Going" is much the worst, 'cos most of it's uphill, so I was much relieved to reach my goal and get a fine eyeballfull up the valley to Penryn and beyond to the blue ridge foothills of the china clay waste up by St Austell. These days the china clay folks get enviromental awards for flattening off the waste piles and making them green to "blend in" with the surrounding countryside (which they don't). But not that long ago they used to be left white and looked like snow-capped mountains, which was much more fun IMO. Heigh ho.

The church itself has an extremely picturesque pathway from the road, down paste high stone walls liberally coated with moss, ferns and worts of some sort, and an exceedlingly solid granite coffin rest and benches at the bottom. Of course that was for the benefit of the poor fellows who used to have to carry the coffin all the way, the church being well outside any of the villages it serves. No-one wants huffing and puffing pallbearers in church. I figured they wouldn't want a huffing and puffing me in the churchyard either, so I took advantage for a while too. That stone chills you to the bone though, so I soon moved on.

The world being as it is isolated country churches are kept locked, so I couldn't go in and look for decorative woodwork, but no matter 'cos there's a wonderful piece of carving in a granite doorframe. The green and orange that looks so extrordinary is actually moulds and lichen I believe - that doorway's in a particularly damp, North-facing spot.

Granite's the building material of choice for the whole church and most of the gravestones, as you might expect given that we're plumb in the middle of a load of granite quarries. Luckily that means the churchyard is spared weeping angels and other difficult-to-carve monuments, but soild oblongs and sturdy crosses abound. Having said which, this slate example caught my eye. Never come across a monumental mason putting a maker's mark on a headstone before. Mind you, Mr Vincent did a lovely job, so why not?

By this time I'd circled round to the other side of the church and was thinking of heading back. But I'd yet to get a halfway decent shot of the church itself. Tsk. Then I looked up from all the Kessels and Dunstans and Spargos and saw I had an Artistic Photo Opportunity. So, embracing the lens flare, I went for the silhouette and took a technically atrocious pic of a typical Cornish church.

Saturday, October 28, 2006

Crime Figures Soar

Good news - lots of workshop time today. Bad news - nope, not tellin' ya about it. On the other hand I've got the okay on a couple of things from Mr Nicholas Blake (see previous on carpenter's stores etc), but I shall save the best for Monday (Mondays need something to sweeten them). In the meantime, anyone want to speculate on the identity of the saw in this incident? Resolution was apparently in Nootka Sound (on the coast of Vancouver Island - and yes, I had to look that up...) in April 1778 and one of the natives

"had nearly got off with a double cross cut saw, used by the carpenters ashore, which he had contrived to twist around his body, and hide under his clothes so ingeniously as almost to avoid suspicion"

Naturally I've made an educated (I'd like to think) guess but if I'm correct it does make the mind boggle a little as to how he managed it. And which way would you have the teeth pointing...?

Oh, and I just know you're all dying for further oakum-toilet paper revelations. Apparently the guides on HMS Victory claim the oakum was hung above the tables at meals for wiping greasy hands on - and then subsequently used for the aforesaid purpose. Now I can recall being quite sceptical about some of the stories those guides put about when I went round Victory many years ago, the leg pull being a favourite hobby of many a nautical type, so take that as you will. I'm certainly not speculating on it - so far every avenue of thought has ended up requiring the delete button if this blog is to refrain from making the readership heave...

"had nearly got off with a double cross cut saw, used by the carpenters ashore, which he had contrived to twist around his body, and hide under his clothes so ingeniously as almost to avoid suspicion"

Naturally I've made an educated (I'd like to think) guess but if I'm correct it does make the mind boggle a little as to how he managed it. And which way would you have the teeth pointing...?

Oh, and I just know you're all dying for further oakum-toilet paper revelations. Apparently the guides on HMS Victory claim the oakum was hung above the tables at meals for wiping greasy hands on - and then subsequently used for the aforesaid purpose. Now I can recall being quite sceptical about some of the stories those guides put about when I went round Victory many years ago, the leg pull being a favourite hobby of many a nautical type, so take that as you will. I'm certainly not speculating on it - so far every avenue of thought has ended up requiring the delete button if this blog is to refrain from making the readership heave...

Friday, October 27, 2006

Checked

Now I could tell you the latest workshop news, but Christmas looms on the horizon, a young galoot's thoughts turn to present-making and blogs have ears. So, in short, I can't. On the other hand I can tell you I now have a clean Stanley #10 bench rebate plane (and some spare parts) where there was only a clean but broken Stanley #10 bench rebate plane and a rusty but unbroken Stanley #10 bench rebate plane before. I'm really going to have make a couple of front knobs sooner rather than later though - a lovely rosewood tote currently being ruined by a flaky old stained beech knob is an abomination unto this galoot's eyes... Other than that, no matter where my thoughts turn, I find myself looking at proscribed topics. Sigh. It's a blighter being full of things to say and not being able to spill the beans for one reason or another. Maybe by Monday at least one thing may have been transferred to the allowed list? Fingers crossed and have a good weekend, y'all.

Thursday, October 26, 2006

Sawyer's Apprentice

Does the bi-annual replacement of the tensioning bolt on my old Elu bandsaw count as bona fide workshop time? For a change this time I had an apprentice to put me off, er, "help" - the old man's been custodian of the saw for a year and more now, so we figured he ought to learn how to do it. It's an Elu 3410 iirc - rebadged as a DeWalt these days (having been a DW before it was rebadged as Elu - what goes around comes around...) and apart from a lousy rip fence the blade tension bolt is the one serious failing it has.

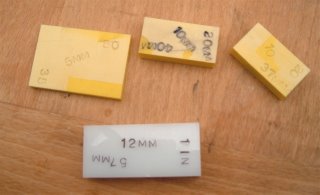

The wallies at DeWally, bless 'em, elected to use a 150mm M6 carriage bolt and an ordinary nut to cope with the tension on the blade. Well it strips the thread on the bolt over time, doesn't it? About once every two years in fact. And DeWalt charge ten whole pounds sterling for a replacement. Naturally I only did that once before I learnt my lesson. Instead I did two things; first, the purchase of a connecting or double nut to help spread the load across more threads - luckily it fits easily in the tensioning knob.

Secondly, should you find yourself in a similar situation, first purchase a 150mm long M6 carriage or coach bolt. Realise the threads as provided aren't long enough so thread them a little further with the correct size of die. You can see from the defunct bolt on the left it's the "proper" threads that give up, not the self-tapped ones.

The tricky bit is dismantling the bolt from the saw without having bearings and washers cascading about your ears. The blade is removed first, then you have to undo the tensioning knob while supporting the weight of the wheel and holding the bolt up in your other hand, and ultimately balancing the small tower of washers and bearing washers on top of the spring while you remove the tensioning knob before swiftly gathering up said tower before letting the bolt slip from the wheel. Whatever you do, you mustn't let the bolt drop out before you've corralled the washers or you'll be on your hands and knees looking for them for a week. Sound complicated? Believe me, it's much worse than it sounds...

But possibly not as bad as putting it all together again... Generally I drop at least one thing as I do so - carefully feeding the washer/bearing tower piece by piece onto the bolt, gradually feeding it upwards as I also support the wheel's weight - and this time it was the tensioning knob. Usually that means dismantling everything again, bending down to retrieve the knob and starting again. Bless the apprentice - as is their purpose in life, he was there to pick it up for me! So instead of prolonged cursing it all went swimmingly first go, and the blade was tracking and the guides set up in no time. And best of all he gets to do it next time instead of me. Huzzah!

I reckon could get used to the idea of having an apprentice...

The wallies at DeWally, bless 'em, elected to use a 150mm M6 carriage bolt and an ordinary nut to cope with the tension on the blade. Well it strips the thread on the bolt over time, doesn't it? About once every two years in fact. And DeWalt charge ten whole pounds sterling for a replacement. Naturally I only did that once before I learnt my lesson. Instead I did two things; first, the purchase of a connecting or double nut to help spread the load across more threads - luckily it fits easily in the tensioning knob.

Secondly, should you find yourself in a similar situation, first purchase a 150mm long M6 carriage or coach bolt. Realise the threads as provided aren't long enough so thread them a little further with the correct size of die. You can see from the defunct bolt on the left it's the "proper" threads that give up, not the self-tapped ones.

The tricky bit is dismantling the bolt from the saw without having bearings and washers cascading about your ears. The blade is removed first, then you have to undo the tensioning knob while supporting the weight of the wheel and holding the bolt up in your other hand, and ultimately balancing the small tower of washers and bearing washers on top of the spring while you remove the tensioning knob before swiftly gathering up said tower before letting the bolt slip from the wheel. Whatever you do, you mustn't let the bolt drop out before you've corralled the washers or you'll be on your hands and knees looking for them for a week. Sound complicated? Believe me, it's much worse than it sounds...

But possibly not as bad as putting it all together again... Generally I drop at least one thing as I do so - carefully feeding the washer/bearing tower piece by piece onto the bolt, gradually feeding it upwards as I also support the wheel's weight - and this time it was the tensioning knob. Usually that means dismantling everything again, bending down to retrieve the knob and starting again. Bless the apprentice - as is their purpose in life, he was there to pick it up for me! So instead of prolonged cursing it all went swimmingly first go, and the blade was tracking and the guides set up in no time. And best of all he gets to do it next time instead of me. Huzzah!

I reckon could get used to the idea of having an apprentice...

Wednesday, October 25, 2006

19thC toilet paper and other mysteries

Further to my blatant looting of "Steering To Glory", I received an email from the author, Mr Nicholas Blake. Yes, trust me to be caught out being rude about a book title again - last time was David Charlesworth's... But no, your correspondent isn't about to be embroiled in legal action (at least not so far), but instead some rather interesting additional info has this way come from Mr Blake. I'm awaiting the nod or no on whether I may post most of it (better safe than sorry), but in case anyone else was as perplexed as me (hence the [?!]) as to the use of "junk axes" and "woolding nails"; apparently junk axes "were used to cut up old rope to be made either into oakum or into tows, for use as the equivalent of toilet paper." Which leads me down a whole different and disturbing road wondering about 19thC toilet paper... However... I sort of pictured all the axes that had seen better days were all kept for some purpose, "just in case". In fact I was thinking that Boatswain must have been a galoot to keep decrepit tools in his stores on the off-chance they'd come in handy, so a bit of a disappointment there. Apparently woolding nails were "used to secure the woolding rope used to support masts or yards that were either fished (broken) or made in pieces." Now that does ring a bell from one or other of the fictional escapades I've read over the years, so I'm quitely kicking myself at not remembering. But no matter. I wonder what their particular attribute was that made them especially suited for the task?

I must admit to thinking it's pretty damn cool to get personal footnotes like that, so very many thanks to Mr Blake. It gets better, but as I say, I don't want to jump the gun without checking first so let's just say I've been practicing my copperplate deciphering today...

Erm, yes... Deciphering copperplate equates to not going into the workshop I fear. Well it was raining buckets anyway - I'd have needed that boat I'm not making.

I must admit to thinking it's pretty damn cool to get personal footnotes like that, so very many thanks to Mr Blake. It gets better, but as I say, I don't want to jump the gun without checking first so let's just say I've been practicing my copperplate deciphering today...

Erm, yes... Deciphering copperplate equates to not going into the workshop I fear. Well it was raining buckets anyway - I'd have needed that boat I'm not making.

Tuesday, October 24, 2006

Pearls before swine

Ladies and gentlemen, we have workshop time! Okay, not much and mainly of the "whoops, shouldn't have left that out all this time" tidying variety, but 'tis definitely much, much better than nothing. Naturally I feel as wobbly as a kitten subsequently, but that's not the point. To my chagrin I found the LN low angle smoother was left out, and as these modern planes seem to have a propensity to do, there's a light hint of oxidisation clouding its ductile loveliness. Makes me feel so ashamed when I let the "good stuff" suffer - what sort of caretaker of them am I, for heaven's sakes...?!

Anyway, I was thinking about my only Auriou rasp (yep, normal service is apparently resumed) and wondering if I'm the only person who finds the handles really, really uncomfortable? It's so thin my hand cramps up having to grip it too hard, the design doesn't give you a natural point to apply forward momentum with your thumb and forefinger and the end that rests in your palm? Ack, it's a slow road to stigmata (hope that doesn't offend anyone). I'm seriously considering replacing the darn thing, which I must admit I object to on a tool costing as much as they do.

Mind you, it's a good example of there being no one perfect handle design. This one, that I hate so much on the rasp, is very similar to the old Henry Taylor gouge also in the pic (and one of the few inherited tools from my grandfather that I have). Now the gouge is small and delicate and that handle just feels right for it. But then I've not been trying to push my way through large quantities of rosewood with it, am I? Perhaps I'm just too heavy-handed with the Auriou - wouldn't be surprised if it was too good for me and I'd be better off with some cheap Chinese verisons. At least the rasp hasn't rusted...

Anyway, I was thinking about my only Auriou rasp (yep, normal service is apparently resumed) and wondering if I'm the only person who finds the handles really, really uncomfortable? It's so thin my hand cramps up having to grip it too hard, the design doesn't give you a natural point to apply forward momentum with your thumb and forefinger and the end that rests in your palm? Ack, it's a slow road to stigmata (hope that doesn't offend anyone). I'm seriously considering replacing the darn thing, which I must admit I object to on a tool costing as much as they do.

Mind you, it's a good example of there being no one perfect handle design. This one, that I hate so much on the rasp, is very similar to the old Henry Taylor gouge also in the pic (and one of the few inherited tools from my grandfather that I have). Now the gouge is small and delicate and that handle just feels right for it. But then I've not been trying to push my way through large quantities of rosewood with it, am I? Perhaps I'm just too heavy-handed with the Auriou - wouldn't be surprised if it was too good for me and I'd be better off with some cheap Chinese verisons. At least the rasp hasn't rusted...

Monday, October 23, 2006

Zzzzzzzzzzzzzzzzz

Now despite my uncharacteristic rash of bloggin' over the weekend and this wholly inaccurate rumour that I'm building a boat (although it is raining an awful lot, so maybe not such a bad idea...), most of the last three days have actually been spent asleep. No, I'm not a student and it's not my usual habit to kip about 20 hours out of every 24, so I swiftly deduce that perhaps that cold is a bit of a sly blighter and has knocked back our heroine rather more than she thought. And of course if helpfully explains the "dunnos" too - nothing like feeling off colour to give you a nasty case of navel gazing, I find. In which case, just as soon as I stop feeling like Wile E Coyote after a strenuous couple of hours chasing the Roadrunner with an Acme anvil tied to each leg, I'll be into the workshop like a young gazelle.

Well, into the workshop anyway...

Which is a cheering thought and lots better than ill-defined "dunnos", although I dunno why... (ho, ho) So in the meantime, if you could just keep the noise down? Ta. Cup of tea about 7am if you would? Cheers. Dammit, this pillow's lumpy though. Headboard's not bad though, eh? Poplar; load of 3ft lengths of 2x2 cunningly wrought into a functional albeit unshowy piece. Got some beading on it, naturally.

D'you know, I think I might be feeling better?

Well, into the workshop anyway...

Which is a cheering thought and lots better than ill-defined "dunnos", although I dunno why... (ho, ho) So in the meantime, if you could just keep the noise down? Ta. Cup of tea about 7am if you would? Cheers. Dammit, this pillow's lumpy though. Headboard's not bad though, eh? Poplar; load of 3ft lengths of 2x2 cunningly wrought into a functional albeit unshowy piece. Got some beading on it, naturally.

D'you know, I think I might be feeling better?

Sunday, October 22, 2006

Carpenter's Stores

Further to the comments on yesterday's post, here's a severely edited version of the list of carpenter's stores as compiled by Captain Bayntun of HMS Milford (74) in 1809 - it seems there was some disagreement about the stores figures so he had the whole kit and caboodle documented and sent off to the Admiralty to prove his point (luckily for us). Quantities are given in Tons, Cwt, Qrs & Lbs, so I'll list 'em with four figures after each item. i.e. Auger bitts (sic) 0.0.0.16 would be 16lbs of same. I'll leave out such items as old canvas, fearnought screens etc but all the tools (blacksmithing as well) and timber are all included and some of the fittings:

Copper nails 0.0.0.12

Rove and clinch 0.0.0.8

Bed bottoms 0.0.1.2

Copper sheet 0.0.2.0

Glue 0.0.0.26

Grindstone 0.0.2.0

Auger bitts 0.0.0.16

Tillers 0.0.0.5 3/4

Bolts, chain plate 0.1.3.24

Bolts, drawn 0.0.1.16

Bolts, drive [to drive out old bolts] 0.0.1.4

Bolts, eye 0.0.0.26

Bolts, ring 0.0.2.4

Bolts, sett [to bring planks together[?]] 0.0.0.14

Bolts, starting [also used as bolts, drive] 0.0.0.4

Chisels, cold 0.0.0.6

Drivers, for hoops on masts 0.1.3.0

Esses for shrouds [s-shaped hooks] 0.2.1.2

Hammers, clench 0.0.0.13 3/4

Sets 0.0.0.7

Cot frames 0.1.0.0

Camp forge, slice [?], hearth staff 0.4.2.0

Anvil 0.2.1.0

Hammers, sledge 0.0.1.20

Hammers, uphand [two-handed, used at forge] 0.0.1.0

Hammers, hand 0.0.0.8

Hammers, bench 0.0.0.1

Hammers, riveting 0.0.0.1

Hammers, nail tool 0.0.0.3

Chisels, cold and hot 0.0.0.3

Bellows, double 0.1.0.12

Files and rubbers 0.0.0.16

Smiths' tongues 0.0.0.16

Hasps and staples 0.0.0.3

Hinges, sorts 0.2.0.15

Hooks, nail 0.0.0.8

Iron, new, of sorts 0.6.0.26

Locks 0.0.0.9

Locks, sorts 0.0.1.9

Loggerheads 0.0.2.0

Mauls, double-headed 0.0.0.23

Nails of sorts 0.6.0.20

Pitch ladles 0.0.0.9

Staples 0.0.0.6

Saw gear 0.0.1.13

Staples, large 0.0.0.2 1/2

Ocham, black 0.5.1.12

Pitch 0.6.0.0

Tallow 0.2.0.22

Tar 0.3.1.7

Bars, capstan, half 0.13.3.10

Board, Elm [Boards being timber 14-18ft long, 8-9in wide and less than 1 1/2in thick] 0.5.1.12

Board, Oak 0.3.2.11

Board, wainscot [Continental Oak for panelling and joinery work, bought by the Navy Board in 1 1/4, 1, and 3/4in thicknesses] 0.3.2.10

Buckets 0.0.1.19

Mess tables 0.15.0.0

Stools for ditto 0.19.2.0

Caulking tools* 0.0.1.27 1/4

Chests of sorts for stores 0.13.0.0

Deals, ordinary [deals 6-14ft long, 9in wide, not more than 3in thick]

Hen coops 0.6.0.0

Moving pantry 0.3.3.0

Plank, Elm, sorts [planks 18ft long or more, 9-10in wide, 1 1/2-4in thick] 0.5.1.12

Plank, Oak 0.5.2.18

Plank, Oak, sorts 0.14.1.16

Screws, wood, with bolt 0.2.0.28

Tables, small 0.4.3.12

Tables, wainscot 0.7.1.0

Tables, sideboard 0.0.2.0

Tillers, spare 1.8.3.10

Treenails 0.3.0.24

Paint 0.2.0.15

Brushes 0.0.0.1 1/2

Oil 0.1.0.8

Black varnish 0.5.0.0

Rulers 0.0.2.0

Lime, bushels [for making whitewash] 0.5.2.24

Ditto brushes 0.0.0.4

Brushes, tar, present use [present use stores were used in fitting out] 0.0.0.5 1/2

Nails, of sorts, present use 0.0.2.19

Tar, present use 0.3.1.7

Board, Elm, present use 0.0.2.10

Deals, ordinary, present use 0.6.0.12

Baulks, present use 0.12.1.3

Wedges, present use 0.1.3.23

*A set of caulker's tools is given elsewhere as:

irons, sharp, 1

horsing, 1

meaking, 1

caulking, 1

crooked, 1

treenail, 1

spike, 1

horsing, large with iron handles,1

beetle, 1

caulking mallet, 1

ladle spout, 1

hook rove, 1

Additionally, in the Boatswain's stores, we find more Black varnish; brushes, large; brushes, tar; cots; another grindstone; axes, junk [?!]; hatchets, mauls for topmasts; scrapers [for cleaning decks]; nails, woolding [?]; and commanders [large wooden mallets].

Honestly, it was a regular floating DIY warehouse come furniture store...

Anyway, if you're interested in "Nelson's Navy", I recommend "Steering To Glory - A Day In the Life of a Ship Of The Line" by Nicholas Blake from which I've filched this stuff. It's a lousy title, but the content is excellent. The only drawback is he's had to use a lot of court martial evidence so there's rather more going on in the cable tier and other dark spots than maybe was strictly true on the average day...

Copper nails 0.0.0.12

Rove and clinch 0.0.0.8

Bed bottoms 0.0.1.2

Copper sheet 0.0.2.0

Glue 0.0.0.26

Grindstone 0.0.2.0

Auger bitts 0.0.0.16

Tillers 0.0.0.5 3/4

Bolts, chain plate 0.1.3.24

Bolts, drawn 0.0.1.16

Bolts, drive [to drive out old bolts] 0.0.1.4

Bolts, eye 0.0.0.26

Bolts, ring 0.0.2.4

Bolts, sett [to bring planks together[?]] 0.0.0.14

Bolts, starting [also used as bolts, drive] 0.0.0.4

Chisels, cold 0.0.0.6

Drivers, for hoops on masts 0.1.3.0

Esses for shrouds [s-shaped hooks] 0.2.1.2

Hammers, clench 0.0.0.13 3/4

Sets 0.0.0.7

Cot frames 0.1.0.0

Camp forge, slice [?], hearth staff 0.4.2.0

Anvil 0.2.1.0

Hammers, sledge 0.0.1.20

Hammers, uphand [two-handed, used at forge] 0.0.1.0

Hammers, hand 0.0.0.8

Hammers, bench 0.0.0.1

Hammers, riveting 0.0.0.1

Hammers, nail tool 0.0.0.3

Chisels, cold and hot 0.0.0.3

Bellows, double 0.1.0.12

Files and rubbers 0.0.0.16

Smiths' tongues 0.0.0.16

Hasps and staples 0.0.0.3

Hinges, sorts 0.2.0.15

Hooks, nail 0.0.0.8

Iron, new, of sorts 0.6.0.26

Locks 0.0.0.9

Locks, sorts 0.0.1.9

Loggerheads 0.0.2.0

Mauls, double-headed 0.0.0.23

Nails of sorts 0.6.0.20

Pitch ladles 0.0.0.9

Staples 0.0.0.6

Saw gear 0.0.1.13

Staples, large 0.0.0.2 1/2

Ocham, black 0.5.1.12

Pitch 0.6.0.0

Tallow 0.2.0.22

Tar 0.3.1.7

Bars, capstan, half 0.13.3.10

Board, Elm [Boards being timber 14-18ft long, 8-9in wide and less than 1 1/2in thick] 0.5.1.12

Board, Oak 0.3.2.11

Board, wainscot [Continental Oak for panelling and joinery work, bought by the Navy Board in 1 1/4, 1, and 3/4in thicknesses] 0.3.2.10

Buckets 0.0.1.19

Mess tables 0.15.0.0

Stools for ditto 0.19.2.0

Caulking tools* 0.0.1.27 1/4

Chests of sorts for stores 0.13.0.0

Deals, ordinary [deals 6-14ft long, 9in wide, not more than 3in thick]

Hen coops 0.6.0.0

Moving pantry 0.3.3.0

Plank, Elm, sorts [planks 18ft long or more, 9-10in wide, 1 1/2-4in thick] 0.5.1.12

Plank, Oak 0.5.2.18

Plank, Oak, sorts 0.14.1.16

Screws, wood, with bolt 0.2.0.28

Tables, small 0.4.3.12

Tables, wainscot 0.7.1.0

Tables, sideboard 0.0.2.0

Tillers, spare 1.8.3.10

Treenails 0.3.0.24

Paint 0.2.0.15

Brushes 0.0.0.1 1/2

Oil 0.1.0.8

Black varnish 0.5.0.0

Rulers 0.0.2.0

Lime, bushels [for making whitewash] 0.5.2.24

Ditto brushes 0.0.0.4

Brushes, tar, present use [present use stores were used in fitting out] 0.0.0.5 1/2

Nails, of sorts, present use 0.0.2.19

Tar, present use 0.3.1.7

Board, Elm, present use 0.0.2.10

Deals, ordinary, present use 0.6.0.12

Baulks, present use 0.12.1.3

Wedges, present use 0.1.3.23

*A set of caulker's tools is given elsewhere as:

irons, sharp, 1

horsing, 1

meaking, 1

caulking, 1

crooked, 1

treenail, 1

spike, 1

horsing, large with iron handles,1

beetle, 1

caulking mallet, 1

ladle spout, 1

hook rove, 1

Additionally, in the Boatswain's stores, we find more Black varnish; brushes, large; brushes, tar; cots; another grindstone; axes, junk [?!]; hatchets, mauls for topmasts; scrapers [for cleaning decks]; nails, woolding [?]; and commanders [large wooden mallets].

Honestly, it was a regular floating DIY warehouse come furniture store...

Anyway, if you're interested in "Nelson's Navy", I recommend "Steering To Glory - A Day In the Life of a Ship Of The Line" by Nicholas Blake from which I've filched this stuff. It's a lousy title, but the content is excellent. The only drawback is he's had to use a lot of court martial evidence so there's rather more going on in the cable tier and other dark spots than maybe was strictly true on the average day...

Saturday, October 21, 2006

I see no ships

Last year it was Blues vs. Reds, fireworks, fleet reviews, you name it. This year, 'cos it's a mere 201 years ago instead of a nice round number, you'd think the Battle of Trafalgar never happened. Tsk, the fickleness eh? Ah well, plenty of public fickleness 201 years ago too (just ask Nelson - well obviously you can't. Even if he'd lived into a ripe old age you're about 170 years too late...) so plus ce change as they say. Unfortunately all too many other things haven't changed either, but luckily I don't do politics. So instead I'll take the woodworkers' perspective and raise a glass to the skilled craftsmen who turned large quantities of oak trees into the formidable feats of engineering that did their best to annihilate each other, and the poor carpenters who had to be there to repair the damage - on both sides.

Friday, October 20, 2006

Neurosis

I'm fairly sure I've blogged about woodworker's block before, haven't I? Not an unfamiliar feeling in most creative disciplines. With woodworking it's usually that first breaking into a new stack of timber that I find difficult. Once there's chippings in the dust extractor and a pile of new prepped boards on the bench, I'm away and will get to the end of the project in one way or another even if (hah! WHEN) there's angst along the way. With writing it's famously the blank piece of paper that's inhibiting, even to the point of writing any old gobbledegook to get oneself starting. It's the same sort of thing as writing postcards; it's only when you're down to the last 1/2" that you suddenly have more to say than can fit so you have to end up crawling up the side to get it in.

Hmm, that would work better if I could lay it out on the screen with the text crawling up the side, wouldn't it? The limitations of computers...

But woodworker's block is not an unfamiliar enemy, and it's dealt with eventually. But I don't usually go totally non-woodworking. It's not often that I'm not thinking of some woodwork-related idea or theory, enthusiatically reading the various forums and so forth. It's not often I reach the point of picking up a Woodworker annual and putting it down again, unread.

I know. Worrying, ain't it? Normality to me is being a Really Sad Case... (Nah, that's not what I meant, but it's a fair point... Anyway.)

I just can't seem to get going at all. Been in a funny mood all week now, to be honest. I better flippin' well snap out of it soon or, well I dunno. That's the problem - I dunno just about sums it up at the moment! Not been a bad week really; a couple of unsolicited tool purchasing enquiries, a little saw doctor work turned up; mysterious envelope of galootishness from BB and so forth, but nope, just can't flick the switch to "on". You know it's bad when TPTBs unexpectedly turn up with a Terry Pratchett in the hopes I'd not got it and it'd cheer me up. Yikes. It'll be an old tool on the off-chance I don't have it next.

So I've tried the go-into-the-workshop-regardless option. The tool-cleaning-aversion-therapy. The don't-think-about-it option and now the blog-your-neurosis-away treatment. (Or should that be blog-your-neurosis-back-again...?) If this doesn't work I'm in real trouble...

Hmm, that would work better if I could lay it out on the screen with the text crawling up the side, wouldn't it? The limitations of computers...

But woodworker's block is not an unfamiliar enemy, and it's dealt with eventually. But I don't usually go totally non-woodworking. It's not often that I'm not thinking of some woodwork-related idea or theory, enthusiatically reading the various forums and so forth. It's not often I reach the point of picking up a Woodworker annual and putting it down again, unread.

I know. Worrying, ain't it? Normality to me is being a Really Sad Case... (Nah, that's not what I meant, but it's a fair point... Anyway.)

I just can't seem to get going at all. Been in a funny mood all week now, to be honest. I better flippin' well snap out of it soon or, well I dunno. That's the problem - I dunno just about sums it up at the moment! Not been a bad week really; a couple of unsolicited tool purchasing enquiries, a little saw doctor work turned up; mysterious envelope of galootishness from BB and so forth, but nope, just can't flick the switch to "on". You know it's bad when TPTBs unexpectedly turn up with a Terry Pratchett in the hopes I'd not got it and it'd cheer me up. Yikes. It'll be an old tool on the off-chance I don't have it next.

So I've tried the go-into-the-workshop-regardless option. The tool-cleaning-aversion-therapy. The don't-think-about-it option and now the blog-your-neurosis-away treatment. (Or should that be blog-your-neurosis-back-again...?) If this doesn't work I'm in real trouble...

Thursday, October 19, 2006

'Rat fink

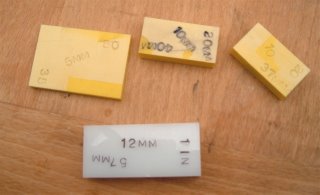

Not often I blog about the Woodrat really, but when you're looking at the bottom of the barrel you scrape up what you may. About a month ago I was moved to make a version of 'Ratter Extrordinaire Aldel's Universal Workholder. And lo', it was good. But I had concerns about the foam board I'd used for the runner, as mentioned here, so when Rutlands had a bit of a sale on everything without a plug, I splashed out on a length of 12mm thick slick UHMW plastic stuff sold for making routing jigs, tablesaw fences and so forth. As it happens, 12mm is just the right thickness for the job and t'was but the work of a moment on the 'Rat to run up a t-shaped piece to replace the foam board. Well worth the effort too - no more sticking but smoooooooth.

Now this stuff can be worked like a rather buttery piece of boxwood - saws, planes, the works. So I had a little play with it, while I was there, trimming a piece on the shooting board and so forth, with a vague view to a project I've had in mind for many years. I think of it as "Woodworker's Feeler Gauges" - like the engineer's variety but of more substantial sizes as would be useful for a woodworker in setting up tools. Now you can buy set up blocks, and indeed I have a set of brass discs in useful thicknesses for that sort of thing, but for setting up my beloved combination planes it'd really be more help if they came in pairs. For before and abaft the cutter, you see? Well I've not done much, but with the various thicknesses of stuff I have about the place I reckon I could get quite a good range of settings. Trouble is I tried getting clever and incorporating useful lengths and widths into the things too, and that's probably a mistake. But as a preliminary recce of the idea, I'm cautiously optimistic. But it's going to take a helluva a long time to make them all at the rate I was going...

The foam board is not as ink-on-wipe-off friendly as the UHMW unfortunately. Heigh ho. I also thought I might try out the stuff as fence material for fenced planes. I mean there's no rule that traditional tools has to mean traditional materials, is there? Next stop garolyte plane soles...*

Other than that I'm in serious "miserable crotchety old bugger" mode and inclined to pick a virtual fight at a drop of a hat. I can only conclude that this is how some forum contributors feel all the time...

*I doubt many readers will get that ref, but it might get a chuckle from at least one

Now this stuff can be worked like a rather buttery piece of boxwood - saws, planes, the works. So I had a little play with it, while I was there, trimming a piece on the shooting board and so forth, with a vague view to a project I've had in mind for many years. I think of it as "Woodworker's Feeler Gauges" - like the engineer's variety but of more substantial sizes as would be useful for a woodworker in setting up tools. Now you can buy set up blocks, and indeed I have a set of brass discs in useful thicknesses for that sort of thing, but for setting up my beloved combination planes it'd really be more help if they came in pairs. For before and abaft the cutter, you see? Well I've not done much, but with the various thicknesses of stuff I have about the place I reckon I could get quite a good range of settings. Trouble is I tried getting clever and incorporating useful lengths and widths into the things too, and that's probably a mistake. But as a preliminary recce of the idea, I'm cautiously optimistic. But it's going to take a helluva a long time to make them all at the rate I was going...

The foam board is not as ink-on-wipe-off friendly as the UHMW unfortunately. Heigh ho. I also thought I might try out the stuff as fence material for fenced planes. I mean there's no rule that traditional tools has to mean traditional materials, is there? Next stop garolyte plane soles...*

Other than that I'm in serious "miserable crotchety old bugger" mode and inclined to pick a virtual fight at a drop of a hat. I can only conclude that this is how some forum contributors feel all the time...

*I doubt many readers will get that ref, but it might get a chuckle from at least one

Monday, October 16, 2006

Neglect

I know, I know - I've been letting the blogging go recently. It's not for want of desire to blog, simply that I haven't really done anything in the workshop to speak of. Usually I'd fall back on theoretical woodworking instead, but my mind's taken up with things for a second article for the Lee Valley email newsletter (Now folks can claim I'm in their pay, and with justification - so naturally they haven't. D'oh!) Not that I don't often manage to think of something else to say when I'm working on a whittering for the web site, but there's something about getting remuneration for writing something I find horribly inhibiting. I'm so wrapped up in not falling foul of the rules and regs of exclusivity and such that I dread to let a word slip - and thus clam up completely in consequence. Silly, isn't it? Still, I've got a couple of ideas swilling about in the old brain cell, so all I need now is some workshop time to implement them.

Oh, and I found myself another tapered reamer. You look for years for one, and then two come along at once - typical. Hah, yes, and also another wad punch... Gimme a "C", gimme an "O", gimme an "L", gimme another "L"...

Oh, and I found myself another tapered reamer. You look for years for one, and then two come along at once - typical. Hah, yes, and also another wad punch... Gimme a "C", gimme an "O", gimme an "L", gimme another "L"...

Wednesday, October 11, 2006

Still aten't dead yet

Although I'm not so sure I won't ask for a recount...

Nah, to be fair I am feeling better. Not well mind you (don't want to relinquish the sympathy too soon, after all...) but definitely less awful. Not to the point of getting into the workshop, alas, but able to lift the occasional volume of The Woodworker to my streaming eyes and make out the odd snippet of interest. 1940 is currently being perused, and I found the following:

"The Stanley Tool Co. make an ever-ready blade which is attached by two screws to a specially constructed blade holder. This arrangement fits practically all their bench planes and assures a sharp cutting edge at all times. It is a boon to the outworker who has not access to a hone or grindstone. The blades are as easy to remove and replace as a razor blade. They are put up in packets of five and six according to the type of plane they are intended to fit."

The right to look smug to the first reader who can provide the name Stanley gave these short-lived wonder blades. Although they seem to have lived longer than I thought, given the 1940 date and the dates I've seen given for them elsewhere - but maybe they just got delayed on the boat over here...

And for the saw fanatics, discussion of the purpose of the "needle test" used on saws. The theory from readers was it was to test the "set" - the noble lords of The Woodworker had doubts, so "to have an authoritative opinion we wrote to the well-known sawmakers, Messrs. Spear & Jackson, of Sheffield, and obtained the following interesting ruling:

"The test with a sewing needle is not to test the set of a saw at all; it is done to test the accuracy of the bevel filing of the teeth of a crosscut saw"

Hold it right there - did S&J actually use this thing then? Or is the "it is done" used in a loose, by-less-accomplished-saw-filers-than-us, kinda way? I have a mental picture of an apprentice saw filer finally being considered good enough to be presented with his official S&J needle... But back to the authoritative ruling:

"In bevel filing the file is held at about 45 deg. (or 60 deg. for saws for hardwood) with the blade, so that each tooth is filed to a keen edge at its outer or cutting edge, and is bevelled well back at the other side... This forms a V-shape when the saw is viewed from the end, and the needle can travel freeling down this."

But now, for me, the really interesting bit:

"It should be remembered, however, that only the best quality crosscut saws are bevel filed. [My astonished bold] Certain cheaper crosscut saws [like 'not Spear & Jackson's' one wonders, reading between the lines?] are filed straight across."

Blah, blah, explains how you couldn't get a needle down one filed like that and that basically if you had enough set to accomplish it you've got way too much set.

But folks, I'm somewhat taken aback at the cheaper crosscut being filed without any fleam thing. Have I somehow overlooked this in the past? Was it not done on cheaper saws 'cos they couldn't take the fleam 'cos of inferior steel? Or just 'cos it's harder flippin' work to get the fleaminess right so they'd charge extra? Is this exciting new evidence for people to argue about, or have I just dozed off in all the discussions and missed it before?

Tune in next week to find out!

Ah hum, sorry, got carried away there. Maybe tune in tomorrow and read the comments pointing out I was indeed asleep instead...

Nah, to be fair I am feeling better. Not well mind you (don't want to relinquish the sympathy too soon, after all...) but definitely less awful. Not to the point of getting into the workshop, alas, but able to lift the occasional volume of The Woodworker to my streaming eyes and make out the odd snippet of interest. 1940 is currently being perused, and I found the following:

"The Stanley Tool Co. make an ever-ready blade which is attached by two screws to a specially constructed blade holder. This arrangement fits practically all their bench planes and assures a sharp cutting edge at all times. It is a boon to the outworker who has not access to a hone or grindstone. The blades are as easy to remove and replace as a razor blade. They are put up in packets of five and six according to the type of plane they are intended to fit."

The right to look smug to the first reader who can provide the name Stanley gave these short-lived wonder blades. Although they seem to have lived longer than I thought, given the 1940 date and the dates I've seen given for them elsewhere - but maybe they just got delayed on the boat over here...

And for the saw fanatics, discussion of the purpose of the "needle test" used on saws. The theory from readers was it was to test the "set" - the noble lords of The Woodworker had doubts, so "to have an authoritative opinion we wrote to the well-known sawmakers, Messrs. Spear & Jackson, of Sheffield, and obtained the following interesting ruling:

"The test with a sewing needle is not to test the set of a saw at all; it is done to test the accuracy of the bevel filing of the teeth of a crosscut saw"

Hold it right there - did S&J actually use this thing then? Or is the "it is done" used in a loose, by-less-accomplished-saw-filers-than-us, kinda way? I have a mental picture of an apprentice saw filer finally being considered good enough to be presented with his official S&J needle... But back to the authoritative ruling:

"In bevel filing the file is held at about 45 deg. (or 60 deg. for saws for hardwood) with the blade, so that each tooth is filed to a keen edge at its outer or cutting edge, and is bevelled well back at the other side... This forms a V-shape when the saw is viewed from the end, and the needle can travel freeling down this."

But now, for me, the really interesting bit:

"It should be remembered, however, that only the best quality crosscut saws are bevel filed. [My astonished bold] Certain cheaper crosscut saws [like 'not Spear & Jackson's' one wonders, reading between the lines?] are filed straight across."

Blah, blah, explains how you couldn't get a needle down one filed like that and that basically if you had enough set to accomplish it you've got way too much set.

But folks, I'm somewhat taken aback at the cheaper crosscut being filed without any fleam thing. Have I somehow overlooked this in the past? Was it not done on cheaper saws 'cos they couldn't take the fleam 'cos of inferior steel? Or just 'cos it's harder flippin' work to get the fleaminess right so they'd charge extra? Is this exciting new evidence for people to argue about, or have I just dozed off in all the discussions and missed it before?

Tune in next week to find out!

Ah hum, sorry, got carried away there. Maybe tune in tomorrow and read the comments pointing out I was indeed asleep instead...

Monday, October 09, 2006

Cornered

Alas, I am undone. Woe is me. You'll be sorry when I'm dead* Etc.

Yes, as you may guess, I'm feeling sorry for myself. What was an irritating freshening of a mild cold on Friday descended on me in force on Sunday lunchtime and I have A Cold. Yea, even unto it being Man 'Flu; not really 'flu at all, but try telling that to any bloke suffering from it... Wrapped myself up in a blanket, dived under the duvet and have been there more of less ever since, feeling (as previously mentioned) sorry for myself. For full effect read this blog entry with periodic sneezes, blowing of nose, mutterings of "damn, where are the tissues" and so forth.

Anyway, apart from that the weather this weekend was dry with hints of sunshine, so I hit a couple of car boot sales while there's still anything there to speak of. Got a handful of old woodworking mags on Sunday; Woodsmith, Wood and Woodworker's Journal, all of which are previously unknown to me. To be honest I think they'll be largely remaining unknown to me in future too. Altogther too much tablesaur stuff for this bandsaw-lovin', hand tool-totin' neander. Funny though; the bloke had them marked up at 20p each, or six for a pound. Well I found five, and paid him the pound. He raised his eyebrows and wordlessly indicated the sign. I looked at the remaining Good Woodworkings and Woodworkers of modern vintage and sadly shook my head - "don't want any of the others". I think he thought I was nuts - long-term readers may fell he has a point of course, but for other reasons...

But Saturday brought my Best Buy - in fact the only thing in the place worth bothering with. There's a character who has a deplorable habit of keeping his stock, mainly tools, in a rusting, leaking old shipping container. I don't know what state the tools are in when they go in, but when they come out they've definitely been introduced to the joys of ferrous oxide. He has most of them displayed in plastic trays on the ground, with the real dregs not even earning a tray, and the select few he thinks are worth something on a table. I have a theory that tools start out on the table, weeks go past and the effects of the shipping container are felt until they are relegated to a tray, Time moves on, and if the tool doesn't, it will eventually make it to the bottom of the social scale and the bare ground. What happens to them then, who knows? Although there are rusty stains on the ground where he usually sets up, so either someone's cut themselves and bleed to death there or the tools become so rusty they actually dissolve and return to the earth. Ashes to ashes, dust to dust...

Anyway, occasionally there's something on the table that's worth paying the slightly inflated price for - a Marples honing guide with instructions, f'rinstance. The trays; well even insane rust remover that I am, I don't bother with the trays. As for the grounded stuff... (shudder) So anyway, I had a look, and what does my wondering eye behold? Actual shiny plated metal! Hey, a joist or corner brace by Skinner! I never, but never see those. Certainly never expected to see one in good order, that's for sure, and certainly not here. And a not insane price!

Friends, it was my duty to save that tool from the fate of another week in the shipping container. Surely you can see that?

So I did.

Already the old man has said "ooo" and "that'd be useful", so its chances of residing in the workshop for any length of time are slim. He does more boring in awkward spots than I do anyway, so I might as well accept the inevitable, clean it up and give it to him for one of his birthday presents. And what's more, he'll probably have forgotten about it by then, so it'll come as a surprise...

* The eternal cry of the wronged eight year old.

Yes, as you may guess, I'm feeling sorry for myself. What was an irritating freshening of a mild cold on Friday descended on me in force on Sunday lunchtime and I have A Cold. Yea, even unto it being Man 'Flu; not really 'flu at all, but try telling that to any bloke suffering from it... Wrapped myself up in a blanket, dived under the duvet and have been there more of less ever since, feeling (as previously mentioned) sorry for myself. For full effect read this blog entry with periodic sneezes, blowing of nose, mutterings of "damn, where are the tissues" and so forth.

Anyway, apart from that the weather this weekend was dry with hints of sunshine, so I hit a couple of car boot sales while there's still anything there to speak of. Got a handful of old woodworking mags on Sunday; Woodsmith, Wood and Woodworker's Journal, all of which are previously unknown to me. To be honest I think they'll be largely remaining unknown to me in future too. Altogther too much tablesaur stuff for this bandsaw-lovin', hand tool-totin' neander. Funny though; the bloke had them marked up at 20p each, or six for a pound. Well I found five, and paid him the pound. He raised his eyebrows and wordlessly indicated the sign. I looked at the remaining Good Woodworkings and Woodworkers of modern vintage and sadly shook my head - "don't want any of the others". I think he thought I was nuts - long-term readers may fell he has a point of course, but for other reasons...

But Saturday brought my Best Buy - in fact the only thing in the place worth bothering with. There's a character who has a deplorable habit of keeping his stock, mainly tools, in a rusting, leaking old shipping container. I don't know what state the tools are in when they go in, but when they come out they've definitely been introduced to the joys of ferrous oxide. He has most of them displayed in plastic trays on the ground, with the real dregs not even earning a tray, and the select few he thinks are worth something on a table. I have a theory that tools start out on the table, weeks go past and the effects of the shipping container are felt until they are relegated to a tray, Time moves on, and if the tool doesn't, it will eventually make it to the bottom of the social scale and the bare ground. What happens to them then, who knows? Although there are rusty stains on the ground where he usually sets up, so either someone's cut themselves and bleed to death there or the tools become so rusty they actually dissolve and return to the earth. Ashes to ashes, dust to dust...

Anyway, occasionally there's something on the table that's worth paying the slightly inflated price for - a Marples honing guide with instructions, f'rinstance. The trays; well even insane rust remover that I am, I don't bother with the trays. As for the grounded stuff... (shudder) So anyway, I had a look, and what does my wondering eye behold? Actual shiny plated metal! Hey, a joist or corner brace by Skinner! I never, but never see those. Certainly never expected to see one in good order, that's for sure, and certainly not here. And a not insane price!

Friends, it was my duty to save that tool from the fate of another week in the shipping container. Surely you can see that?

So I did.

Already the old man has said "ooo" and "that'd be useful", so its chances of residing in the workshop for any length of time are slim. He does more boring in awkward spots than I do anyway, so I might as well accept the inevitable, clean it up and give it to him for one of his birthday presents. And what's more, he'll probably have forgotten about it by then, so it'll come as a surprise...

* The eternal cry of the wronged eight year old.

Friday, October 06, 2006

Aversion therapy

I know what you're thinking - she's slipping. Missed a day and now repeating a post. But it's not the same plane, honest, This is the other #4.5 that's been waiting about for me to clean it up. I took it all to pieces and gave it a scrub, ooo, months ago, but it's been waiting around asking to lose parts ever since. So I bit the bulet at last. Not that it can complain - it was in the toolchest so that's only, what, two and a half years ago... It's the one top left in this pic:

Not the prettiest then, and not really the prettiest now, but would make a good user I reckon. Of course I don't have time to tune it up, so I'll probably have to find a new home for it at a cut rate. Type study makes it to be a 15 - 1931-1932 - which ties in pretty well with the other Stanleys in the box iirc. What it has demonstrated to me is that my tote is considerably clunkier than it ought to be - those old rosewood totes are really incredibly elegant.

I also cleaned up the #79 side rebate I got last month, de-rusted the iron of the lignum vitae coffin smoother and found it correct size cap iron (still needs the wedge), cleaned the Ward & Payne chisel (still needs a lot of work on the back, and a new handle natch), oh and cleaned the guides of the Marples mitre box. On inspection the box isn't in any too great shape, so as I'd thought, I dug out the as-new Crown, put a quick groove in the top for the guides and set it up as my brand spanking new improved mitre box.

And I still know what you're thinking. You're thinking "Alf, this is a good deal of prevaricating about the bush - what about the saw till?"

It's aversion therapy.

I reckon if I do enough tool cleaning I'll get so fed up with the dirt, mess and general mechaniciness of the workshop that I'll be desperate to get back to the cleanliness of working wood again. Plus I get cleaned tools where before there was rust. They'll still be in the way mind you, but at least they won't leave dirty marks...

Oh, and for eager viewers of ParrotCageWatch - got a call to say the colour I'd chosen was out of stock, so three week delay. The suspense is killing me; how about you?

Tuesday, October 03, 2006

Tote-ally Crazy

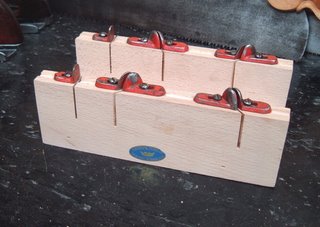

Not a word vis-a-vis arrival or otherwise of cage, but the free gift I hadn't realised I was getting arrived:

Sort of appropriate get-up for a more Normite parrot, no? But with a beak like that I reckon the pliers are a bit superfluous quite frankly...

In a continuing bid to prevaricate over the saw till, more handle-making struck. At least this is clearing up a few "To Do's" on the list - this one's been waiting only about 5 years for a rear tote... A very early purchase, this #4.5, came equipped with a modern plastic handle that neither fitted nor suited it. I think it's something like a type 8 or 9, so turn of the century.

Trouble is the luscious low front knob is awful dark - possibly been treated with BLO at some point which can turn rosewood almost black. Dunno whether to refinish in the hopes it might lighten up a bit or not. Really I ought to be making the unoriginal tote darker, I know, but with that gorgeous streak of colour through it? Not perishing likely. While I was at it I figured a little cleaning up to bring out her looks wasn't a bad idea; my idea of plane cleaning has changed a bit in five years and I'm less tolerant of some patina than I used to be. It's like the phenomenom of putting away a seldom used tool "sharp", only to find it's mysteriously got blunt when you return to it. It's simply your notion of "sharp" has changed in the intervening time. May have done myself a bit of a disservice in fact; looks so sparkling now I'm wondering about an aftermarket blade and cap iron... Oh deary me.

Sort of appropriate get-up for a more Normite parrot, no? But with a beak like that I reckon the pliers are a bit superfluous quite frankly...

In a continuing bid to prevaricate over the saw till, more handle-making struck. At least this is clearing up a few "To Do's" on the list - this one's been waiting only about 5 years for a rear tote... A very early purchase, this #4.5, came equipped with a modern plastic handle that neither fitted nor suited it. I think it's something like a type 8 or 9, so turn of the century.

Trouble is the luscious low front knob is awful dark - possibly been treated with BLO at some point which can turn rosewood almost black. Dunno whether to refinish in the hopes it might lighten up a bit or not. Really I ought to be making the unoriginal tote darker, I know, but with that gorgeous streak of colour through it? Not perishing likely. While I was at it I figured a little cleaning up to bring out her looks wasn't a bad idea; my idea of plane cleaning has changed a bit in five years and I'm less tolerant of some patina than I used to be. It's like the phenomenom of putting away a seldom used tool "sharp", only to find it's mysteriously got blunt when you return to it. It's simply your notion of "sharp" has changed in the intervening time. May have done myself a bit of a disservice in fact; looks so sparkling now I'm wondering about an aftermarket blade and cap iron... Oh deary me.

Monday, October 02, 2006

New home for the winter

'Tis a shaming thing to look back and find I was discussing new housing for Bertie, my African Grey, as far back as May and yet only now have I actually placed the order. Naturally I've now got cold feet about it, but getting him to go in it without panicking and falling to the bottom in a tizzy will at least give me something to do with the long winter evenings. 'Cos the nights are really drawing in now; a scent of woodsmoke in the evening air instead of the whine of Flymos; classic drama on the Beeb... Sigh. I must be getting old; I dread winter more and more every year (and not just because of the classic drama). It seems such an achingly long time until the days lengthen again and everyone cheers up. Oh well, looking at it another way, winter means timber felling time, so it's not all loss. I wonder when might be a good time to talk to the Wood Guy again...?

This weekend's activities? The gavel and block was well received. Luckily the Ancient One is afraid to ruin it by banging it too hard, so no worries! And the Saw Till? Tsk, haven't even settled on any dimensions yet. So far successful displacement activity has saved me from any danger of decision-making; nothing new there then...

This weekend's activities? The gavel and block was well received. Luckily the Ancient One is afraid to ruin it by banging it too hard, so no worries! And the Saw Till? Tsk, haven't even settled on any dimensions yet. So far successful displacement activity has saved me from any danger of decision-making; nothing new there then...

Subscribe to:

Comments (Atom)