The intermittant, verging on non-existant connection at the end of last week seems to have passed and normal service should resume. Or what passes for normal anyway... You may have been wondering what I was indulging in funny angled dovetails for? Read on...

So, the board of choice for this thing was a wooly, soggy, warped monstrosity that might be Sapele; part of a pallet of offcuts purchased from

South London Hardwoods at least five years ago. When I say "of choice" naturally I lie. But this is a workshop thing so I use what I have and at least it's fairly light (required) and should be well acclimatised to the w'shop by now. I should have taken the hint when, after planing it up and leaving it

weighted down overnight, it had managed to move some more next morning. But naturally I didn't.

Now it turns out these skewed dovetails are great for subtle bragging rights amongst the woodworking cognoscenti - to do them "properly" you simply can't use a jig, at least not according to Steve

here. Well who am I to argue? So first thing first, pinch that tip for marking out...

Then find out you can't see where your

Cosmanesque divider markings are, so set up a couple of bevels, one for each angle, and do it the hard way. I knew buying really rusty sliding bevels was a Good Thing and here's the justification. I like this joint already.

This was the first real workout the LN saw's had since I got it back in November. Oh the shame. But then there isn't much call for dovetails in a chair to be fair. Anyway, it did a good job and I felt it was probably money well spent. Except I shouldn't have let the show go to my head like that and got one from Mike instead, but you know how it is when the darn thing's right in front of you

and you can take it home right now. Yes, I'm very shallow, I know.

So the old coping saw was broken out for removing the waste - one of these days I may find a decent coping saw that doesn't twist itself into a helix as soon as you try to tension it, but this Bahco one ain't it. Then paring, well chopping back to the line. It's no good kidding myself I can tell if a chisel is plumb or not, 'cos I can't. So I cheat a little and hold a squared offcut behind the chisel to guide it square. It's like those smart jigs folks make, with a bar that clamps down across the baseline, except it takes less room and still involves a little risk to enable me to kid myself that I'm not really cheating at all.

The result justifies the means, I reckon. 'Course the gauge mark to register the chisel is half the battle, and once again the little 3-in-1 jobbie did the biz. Mind you it ruined the LN theme to my main dovetailing tools but while it still works so well how can I even justify a TiteMark look-a-like?

Seeing as the Sapele was soft, I came over all brave and went to glue the joint up first shot, again under the terrible influence of Mr Cosman. And I would have got away with it too, 'cos the fit is actually very good say it I shouldn't - no little fillets of wood filling the gaps there, my friends. But the blasted wood warped didn't it? Despite my best efforts I ended up with three right angles and one of about 50°, which shouldn't be possible. By the time I'd glued in the base and screwed the chestnut handle in place it was a bit better, but there are slight gaps at the insides of the base of the joints where the wood just insisted on ballooning out. Yeah, I should have clamped it, I see that

now, but my joints were tight, I thought they'd do the job! And the darn thing's angled and therefore awkward to clamp. But yeah, I should have. Oh well, another lesson learnt. The sides only being 3/8" thick didn't help.

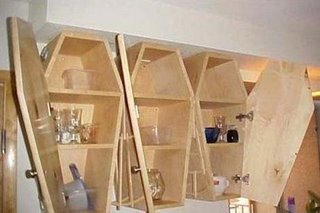

And the finished article? Well you can only wander from the workshop to the garage where the lathe is a certain number of times with your hands full of blanks, chucks, rules, pencils, abrasives, finishes, drawings, plans, centre finders, scattering half of same in your wake, before you start wondering why you don't just make yourself something to carry them all in...